Horizontal Directional Drilling

Our team has numerous years of experience involved in directional drilling with over 1000 HDD (Horizontal Directional Drilling) crossings, both domestic and international.

Huxted Trenchless, formerly operated as ECI Drilling International, was founded with the purpose of providing clients an alternative to conventional methods of placing product lines under streams, rivers, lakes, marshes, wetlands, beaches, estuaries, highways, railways, runways, sand dunes, protected habitats, and other sensitive areas.

Our team has numerous years of experience involved in providing directional drilling services with over 1000 HDD (Horizontal Directional Drilling) crossings, both domestic and international. HDD projects include drilling in all types of rock and alluvial soils; placement of power and communication conduits; single duct for fiber optics including multiple ducts for copper and fiber cables; and product pipe installations.

Our strength lies in our ability to integrate and apply ongoing, high quality, state-of-the-art drilling technology.

- Reduced disruption of the community

- Reduced liability for personal injury and property damage

- Increased service life and asset value for the utility owner

- Increased worker safety

- Reduced restoration costs

- Precise installation

Horizontal Directional Drilling

Communities are continuing to grow and with that new and improved infrastructure is in high demand. Huxted Trenchless, formerly operated as ECI Drilling International, provides Horizontal Direction Drilling services across various industries including oil & gas. Having been open since 1997, Huxted Trenchless, formerly operated as ECI Drilling International, understands the land and how it continues to develop. With a deep knowledge of the land and a trusted, reputable history, Huxted Trenchless’s reputation and quality of work have allowed them to work with the same owners and prime contractors on multiple projects.

Due to all of the ongoing construction in the United States, there is an increased need for horizontal directional drilling services. Oil and gas are two of the most in-demand pieces of infrastructure in need of HDD services. Since horizontal directional drilling can be accomplished with minimal impact below an array of landscapes and cityscapes, it has become the go-to technique to install new or replacement lines.

What are the Benefits of Horizontal Directional Drilling?

Using HDD provides us the opportunity to drill below important infrastructure that is already in place, such as roadways, waterways, and environmentally protected areas, which leads to limited traffic disruption and minimal damage to the area’s landscape. With conventional trenching methods, this is not always possible, which has made HDD an ideal solution.

Other benefits that come with horizontal directional drilling in lieu of conventional trenching methods include quicker turnaround times, minimal environmental impact, more cost-efficient, and the ability to drill directionally.

What Type of Projects Are Ideal for Horizontal Directional Drilling?

Horizontal directional drilling can be utilized for a wide variety of construction projects. Some of these projects include:

• Utility lines

• Communication and fiber optic lines

• Waterlines

• Sewer lines

• Gas lines

When to Consider Using Horizontal Directional Drilling?

In order to determine if you should be using horizontal directional drilling, ask yourself the following questions:

• What are the installation lengths? Is it over 180ft?

• Are you installing in urban areas?

• Are you installing in areas environmentally protected?

• Are you installing in a residential area?

• Is the underground area of the location you’ll be drilling crowded with other utilities?

• Is the pipe that you’ll be installing below a water table?

• How is the soil? Is it unstable?

Horizontal Directional Drilling for Oil and Gas

Improvements and new infrastructure often requires the construction of underground utilities such as natural gas lines, oil lines, or product pipelines. The new lines or replacement lines can be constructed under roads, cities, and neighborhoods as well as natural elements like rivers or wetlands. Construction for new pipes can be accomplished a number of ways but Horizontal Directional Drilling (HDD) offers a more unique, cost effective approach.

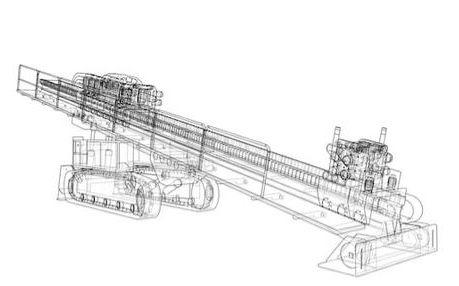

HDD is a trenchless installation technique, minimizing disruption to the environment and area around the construction site. The trenchless option of Horizontal Directional Drilling, can install new lines that span thousands of feet with piping varying in diameter size from small to large.

HDD Projects for the Oil and Gas Industry

Huxted Trenchless, formerly operated as ECI Drilling International, has worked on countless projects within the oil and gas industry since its founding in 1997. Some recent projects include the Epic Pipeline Spread #4 in Carrizo Springs, TX which called for 2 drills at 2,800ft in length with 24in diameter steel pipe, and the Piedmont Natural Gas Line 427 in Rocky Mountain, NC which included five crossings totaling up to 9,328ft with 16in diameter steel pipe.

HDD APPLICATIONS

HDD EQUIPMENT

Description |

Push/Pull Capacity |

Practical Length Capacity |

|---|---|---|

| HRE 1100 | 1,100,000 lb. | Max Drill Lengths 8,000’ + Max OD 48” + Pipe |

| HRE 500 | 500,000 lb. of pullback | Max Drill Lengths 8,000’ + Max OD 48” + Pipe |

| American Augers DD-330 | 330,000 lb. | Max Drill Lengths 5,600’ Max OD 42” Pipe |

| American Augers DD-240T Rig | 240,000 lb. of pullback | Max Drill Lengths 4,400’ Max OD 36” Pipe |

| American Augers DD-210 | 210,000 lb. | Max Drill Lengths 4,400’ Max OD 36” Pipe |

| Vermeer 100×140 | 100,000 lb. | Max Drill Lengths 2,500’ Max OD 24” Pipe |

SAFETY IS OUR #1 PRIORITY

We are committed to achieving an accident free workplace. Proactive involvement, personal responsibility, personal accountability, and continuous individual improvement are expected of all employees, subcontractors, vendors and clients. Safety is of utmost importance in the planning of all directional drilling services, and every one of our employees embrace his/her role in successfully implementing our Safety Program.